Shear Strain Gauges for Torsion and In-Plane Shear Measurement

A shear strain gauge is a specialised foil strain gauge designed to measure in-plane shear strain rather than simple tension or compression. At MFL Strain Gauges (based in N. Ireland), our shear gauges are engineered for applications where components experience torsion, shear dominant bending, or complex stress states converting shear deformation into a clean, reliable electrical signal for test and measurement. Usual resistance requirements range between 120Ω - 2,000Ω (Ohms). MFL can custom design and manufacture to your exact requirements. We also have thousands of Strain Gauges in STOCK ready to ship in a range of sizes with NEXT DAY DELIVERY within UK & IRELAND.

What is a shear strain gauge?

What is shear strain?

Shear strain is the distortion that occurs when layers of material slide slightly relative to each other common in beam webs, bonded interfaces, and shafts under torque. A shear strain gauge is designed to capture this effect directly.

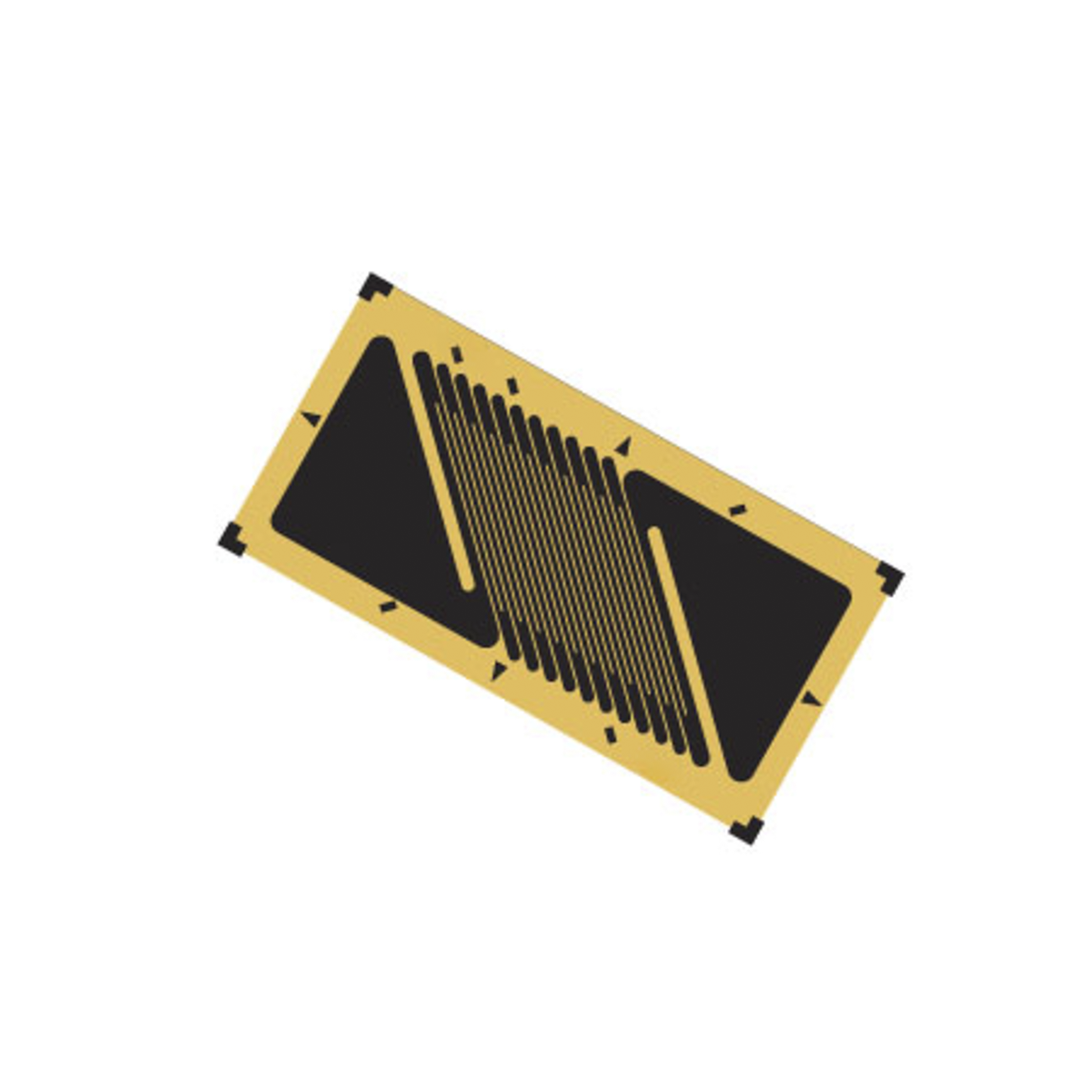

Optimised grid layout (±45° / X-pattern)

Shear strain gauges typically use two foil grids arranged at +45° and −45° to a main axis, or a dedicated X-pattern. When wired correctly, axial strain effects can be reduced while the shear component is emphasised—ideal for torsion and shear-dominant regions.

High sensitivity to in-plane shear

By design, a shear gauge responds strongly to in-plane shear and is less sensitive to uniform axial strain, simplifying measurement in complex stress fields.

Precision foil on polyimide backing

MFL shear gauges use precision etched metal foil on a thin polyimide carrier, providing strong bonding, flexibility, and long term stability while minimising influence on the underlying structure.

Correct orientation and installation allow a shear strain gauge to provide a direct electrical measurement of shear strain, making analysis easier in shear-critical components.

Typical applications for shear strain gauges

1) Torsion and torque measurement on shafts and tubes

One of the most common uses is torque measurement on rotating components:

Drive shafts, steering columns, and powertrain components

Test rigs, dynamometers, and rotating machinery

Tubes, couplings, and hollow shafts

By placing gauges at ±45° to the shaft axis and forming a bridge, torque can be measured accurately with reduced sensitivity to bending.

2) Beam webs and structural members (shear verification)

In many structures, shear in beam webs is a key design factor:

I-beam webs in steel structures, cranes, and lifting frames

Spar webs in aerospace wings and tail sections

Vehicle chassis frames and roll structures

Shear gauges support design validation, FEA correlation, and real-world load path monitoring.

3) Adhesive joints and bonded interfaces

Shear strain is central to the behaviour of bonded joints:

Adhesively bonded metal or composite joints

Bonded stiffeners, doublers, and patches

Interfaces between dissimilar materials

Shear gauges placed near the bond line help characterise load transfer, identify potential failure modes, and support durability testing.

4) Shear panels, plates, and composite laminates

In thin walled and composite structures, shear often dominates:

Shear panels in aircraft, marine, and automotive structures

Composite laminates under in-plane shear or combined loading

Sandwich panels with shear-carrying cores

Shear gauges provide direct in plane shear measurement rather than relying only on inferred values from axial strain data.

5) Experimental mechanics and research

Shear gauges are widely used in R&D environments to:

Study complex stress states and material behaviour

Validate analytical theories and numerical models

Investigate failure mechanisms in shear-critical components

Options and customisation with MFL Shear Gauges

To suit different geometries, installation constraints, and environments, MFL shear strain gauges are available with:

A range of grid sizes to match strain gradients and available mounting area

Multiple lead styles to suit routing, space constraints, and connection preferences

Optional encapsulation when additional environmental or handling protection is required

If you’re unsure which configuration best suits your application, we can recommend an appropriate pattern, grid size, and lead style based on your component and loading conditions.

Why choose MFL Strain Gauges for shear applications?

As a N. Ireland based foil strain gauge manufacturer, MFL offers shear gauges that are:

Precisely patterned for high sensitivity to in plane shear

Stable and consistent, ideal for multi gauge Wheatstone bridge configurations

Built on robust polyimide backing, with encapsulation & leads available where required

Whether you’re measuring torque on a rotating shaft, shear in a beam web, or load transfer in a bonded joint, MFL shear strain gauges provide an accurate, dependable solution for capturing the data you need.

Shear strain gauge FAQs

How do shear gauges measure torque on a shaft?

Gauges are typically oriented at +45° and −45° to the shaft axis and connected in a bridge so the torsional shear signal is emphasised while bending effects are reduced.

Do I need a special wiring configuration?

Most shear applications use a Wheatstone bridge (often a full bridge for torque) to maximise sensitivity and improve temperature effects.

Can you supply different grid sizes and lead styles?

Yes—MFL offers a range of grid sizes and lead styles to suit different component sizes and installation needs, with encapsulation available if required.

Need help choosing a shear gauge?

Contact MFL Strain Gauges with your material, geometry, loading type (torsion/web shear/bonded joint), and environment and we’ll recommend a suitable configuration.