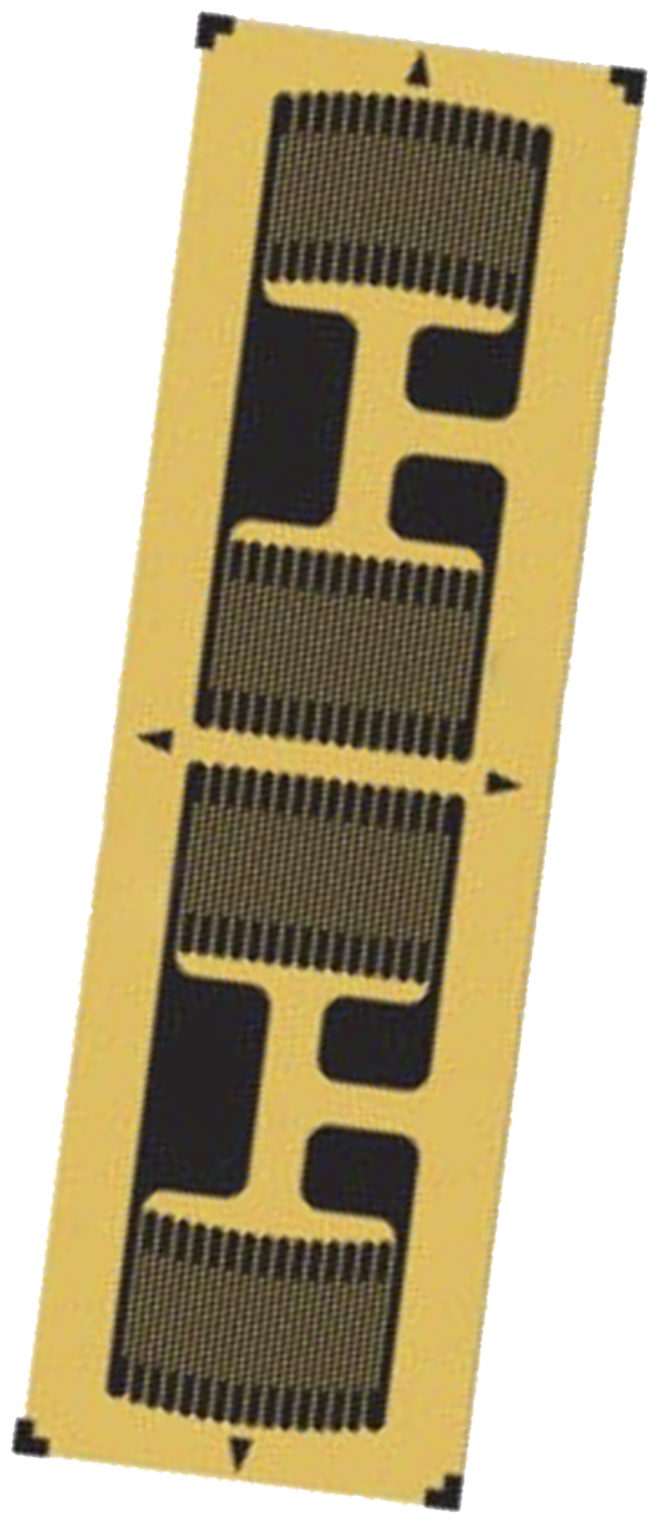

Linear Diaphragm

Strain Gauges for Pressure Transducers — MFL Strain Gauges

A linear diaphragm strain gauge is a specialised foil strain gauge designed to measure strain on thin diaphragms used in pressure transducers, differential pressure sensors, and other diaphragm-based sensing elements. At MFL Strain Gauges (based in N. Ireland), our linear diaphragm gauges are optimised to capture radial or circumferential (tangential/hoop) strain created as a diaphragm deflects under pressure converting that tiny deflection into a stable, linear electrical signal. Usual resistance requirements range between 120Ω - 2,000Ω (Ohms). MFL can custom design and manufacture to your exact requirements. We also have thousands of Strain Gauges in STOCK ready to ship in a range of sizes with NEXT DAY DELIVERY within UK & IRELAND.

What is a linear diaphragm strain gauge?

Designed for diaphragm geometry

Unlike a general-purpose linear strain gauge, a diaphragm gauge is laid out and sized specifically for flat or slightly curved diaphragms. Grid dimensions and resistance are selected to suit the diaphragm’s strain field and sensor design.

Single direction sensitivity (radial or circumferential)

A linear diaphragm gauge measures strain along a defined axis, typically radial or circumferential. This allows accurate placement at high-sensitivity regions of the diaphragm for an improved signal-to-noise ratio and repeatable output.

Precision foil on thin polyimide backing

MFL diaphragm gauges use precision etched metal foil on a thin, flexible polyimide backing to minimise added stiffness. This helps preserve the diaphragm’s natural mechanical behaviour while maintaining strong bonding and long-term stability.

When installed correctly, a linear diaphragm strain gauge follows diaphragm deflection closely, producing a repeatable and linear response to pressure or force.

Typical applications for linear diaphragm strain gauges

1) Pressure transducers and pressure transmitters

The most common application is in pressure sensors where a metal, alloy, or ceramic diaphragm acts as the primary sensing element:

Industrial process pressure transmitters

Hydraulic pressure sensors and controls

HVAC and refrigeration pressure sensing

Pressure test and calibration rigs

Diaphragm gauges are bonded at locations of maximum strain and commonly wired in a Wheatstone bridge to generate an output voltage proportional to applied pressure.

2) Vacuum and differential pressure measurement

Thin diaphragms are highly sensitive in low-pressure applications:

Vacuum gauges and monitoring systems

Differential pressure sensors across filters, orifices, and flow elements

Cleanroom and environmental pressure monitoring

Linear diaphragm gauges offer high resolution and good long-term stability, even with very small diaphragm deflections.

3) Force and load measurement using diaphragm structures

Diaphragms can act as elastic sensing elements in compact force or load devices:

Miniature force transducers

Thrust and load sensing in compact assemblies

Clamping force monitoring in fixtures and tooling

By tailoring diaphragm geometry and gauge placement, sensors can be tuned for range, stiffness, sensitivity, and overload performance.

4) Fluid level and flow-related measurement (via pressure)

Diaphragm-based sensors are also used indirectly for:

Hydrostatic level measurement (pressure at the bottom of a tank)

Flow measurement using differential pressure (orifice / venturi)

The diaphragm converts pressure into strain, and the strain gauge converts that strain into a measurable electrical signal calibrated to level or flow.

Why choose MFL Strain Gauges for diaphragm applications?

As a N. Ireland-based foil strain gauge manufacturer, MFL provides diaphragm gauges that are:

Engineered for linearity and low hysteresis in diaphragm strain fields

Manufactured with tight tolerances for multi-gauge Wheatstone bridge configurations

Supplied on robust polyimide backing suitable for a wide range of environments

Whether you’re designing a new pressure transducer or refining an existing sensor, MFL linear diaphragm strain gauges provide a precise and stable foundation for pressure measurement.

Linear diaphragm strain gauge FAQs

Where should a diaphragm strain gauge be placed?

Placement depends on diaphragm geometry and boundary conditions, but gauges are typically located in regions of peak strain (radial or circumferential) determined by design rules or FEA.

Do diaphragm gauges work for differential pressure sensors?

Yes—linear diaphragm gauges are commonly used in differential pressure designs, where small deflections must be measured accurately and repeatably.

How is the output measured?

Most diaphragm sensors use a Wheatstone bridge (often half or full bridge) to maximise sensitivity and temperature compensation, producing a voltage output proportional to pressure.

Need help selecting a diaphragm gauge?

Contact MFL Strain Gauges with your diaphragm material, thickness, diameter, target pressure range, and preferred bridge configuration and we’ll recommend a suitable diaphragm gauge layout.

Related Strain Gauge Types (MFL)

Shear strain gauges for torque and in-plane shear measurement

Circular strain gauges for hoop strain and strain around holes

Dual strain gauges for bending measurement and temperature compensation

Full bridge strain gauges for load cells and high-output measurement

Rosette strain gauges for principal strain and multi-axis strain analysis